Estimated Ship Date

Walk onto any jobsite early in the morning and you’ll hear it before you see it. The deep rumble (or cacophonous clatter, depending on how cold it is) of a diesel firing up, the sharper bark of a gas V8 turning over, and the mix of trucks parked with toolchests, ladder racks, and utility boxes. For contractors, the pickup isn’t just transportation - it’s a work partner. It hauls tools, tows trailers, and doubles as a mobile office. And the debate over whether gas or diesel really delivers the better return has been raging for decades.

Diesel guys will tell you their trucks last forever. Gas owners will say theirs costs less and still gets the job done. The truth is, it depends on the work you’re doing, how long you keep your trucks, and what you’re willing to put up with in maintenance.

So, which pickup really pays off for contractors in the long run? Let’s break it down.

The gas vs. diesel argument didn’t really heat up until the late 1980s and 1990s when heavy-duty pickup trucks began offering turbocharged diesel engines as factory options. Before then, diesel was largely reserved for big rigs, farm trucks, and equipment. Contractors who wanted a truck that could tow and last longer than the average V8 suddenly had options like the Ford Power Stroke, the Dodge Cummins (recognized as the first turbo diesel heavy duty truck offered to the consumer market in 1989), and GM’s Duramax.

From there, lines were drawn. Diesel enthusiasts praised the torque and longevity, while gas owners leaned on lower purchase prices and simpler upkeep. Fast forward to today, and the decision has only gotten more complicated with emissions regulations, fuel prices that swing wildly, and advanced gas engines that have closed the performance gap.

The first thing contractors notice when comparing gas and diesel pickups is the sticker price. On average, a diesel-equipped heavy-duty truck costs $8,000 to $12,000 more than its gas counterpart.

For example, a Ford F-250 with the 6.8L gas V8 starts thousands (almost 13.5 THOUSAND) less than the same truck spec’d with the 6.7L Power Stroke diesel. Chevrolet’s Silverado HD shows a similar spread, with the 6.6L gas V8 undercutting the 6.6L Duramax diesel.

Contractors buying fleets feel this difference in a big way. As one fleet manager in Texas put it, “If I’m buying ten trucks at once, going diesel adds almost six figures to the cost before they even leave the lot.”

For smaller contractors or owner-operators, that upfront cost can be tough to justify. But diesel buyers argue that the long-term benefits balance it out.

Traditionally, diesel pickups offered a big advantage in miles per gallon, especially under load. Contractors hauling heavy trailers or carrying constant payloads often see diesel efficiency shine.

A 2024 Ram 2500 with the Cummins turbo diesel can average 20+ mpg unloaded on the highway, while its gas sibling struggles to top 15 mpg. Add in towing, and the diesel tends to hold its efficiency much better than gas.

But fuel prices complicate the story. According to AAA’s national averages, diesel often costs anywhere from $0.50 to $1.50 more per gallon than gas, depending on region and season. In northern states during winter, diesel prices can spike due to heating oil demand.

When it comes to sheer pulling power, diesel still rules. Torque is what gets heavy trailers moving, and modern diesels deliver massive amounts of it at low RPMs.

The Ford 6.7L Power Stroke puts out 1,200 lb-ft of torque in its latest iteration. Compare that to the 7.3L gas V8’s 485 lb-ft and you start to see why diesel loyalists won’t budge.

For contractors who tow equipment trailers, dump trailers, or even mini-excavators daily, this extra torque isn’t just nice to have - it’s essential. We always hear sentiments like “My diesel doesn’t even notice a 12,000-pound trailer, my gas truck will pull it, but you feel it working hard the whole time.”

That said, gas engines have improved dramatically. With stronger transmissions, better gearing, and bigger displacements, gas pickups can now tow more than ever. For moderate loads, the difference isn’t as dramatic as it once was.

Here’s where the debate often takes a turn. Diesel engines are built to be heavy-duty, but that doesn’t mean they’re cheaper to keep on the road.

Oil changes on diesels often require 3 to 4 gallons of oil compared to 6 to 8 quarts for a gas engine. Fuel filters, DEF fluid (diesel exhaust fluid), and high-pressure injection systems add complexity and cost.

When something major breaks, the repair bill can be staggering. A set of diesel injectors can cost upwards of $4,000 for parts alone, while turbo or emissions system failures can push repairs even higher.

Gas engines, while not immune to issues, are generally cheaper to repair and require less specialized service. With gas trucks, you can find a mechanic on every corner. With diesel, sometimes you have to drive a ways just to get to someone who knows what they’re doing.

One of diesel’s biggest selling points has always been engine life. It’s not uncommon to see Power Strokes, Duramaxes, and Cummins engines surpass 300,000 miles with proper care. Some even cross the half-million mark.

Gas engines have historically lagged in this department, with many fading after 200,000 miles. But modern gas V8s are narrowing that gap. The Ford 7.3L “Godzilla,” GM’s 6.6L gas, and Ram’s HEMI engines are proving more durable than past generations.

Contractors who turn over trucks every five years may never see the full benefit of diesel longevity. But those who keep trucks for a decade or more might.

“I run my diesels till the wheels fall off,” said one excavation contractor in Pennsylvania. “My 2008 Ram Cummins is still pulling every day with 410,000 miles. You can’t get that out of a gas motor.”

One overlooked factor in the gas vs. diesel conversation is weight. Diesel engines are significantly heavier, often by 700 pounds or more. That weight sits over the front axle, eating into payload capacity.

For contractors who prioritize bed capacity for tools, materials, or equipment, a gas truck can actually carry more, even if it can’t tow as much.

As MotorTrend noted in a comparison test, “The gas F-250 out-carried the diesel by nearly 1,000 pounds due to the lighter engine.”

This matters for contractors loading pallets of concrete, stacks of lumber, or jobsite tools every day.

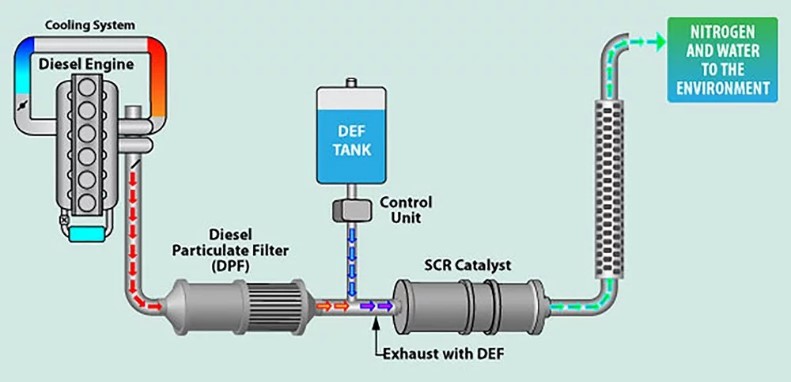

Since 2007, diesel pickups have been saddled with increasingly strict emissions equipment - EGR systems, DPF filters, SCR with DEF injection. While this has made them cleaner, it’s also added complexity and potential headaches.

DEF systems can freeze up in cold weather, DPF filters clog under short-trip driving (unfortunately I know this pain), and sensors fail. Contractors who primarily do city driving may find diesel systems more trouble than they’re worth.

Gas engines, while less fuel-efficient, generally avoid these complications. As emissions regulations tighten further, the long-term outlook for diesel in light-duty trucks is uncertain.

Here’s a category where diesel often wins back ground. Used diesel trucks command strong prices, especially when well maintained. A contractor selling a five-year-old diesel with 150,000 miles might get thousands more than the same truck with a gas V8.

But resale depends heavily on region. In rural areas, diesel demand stays high. In cities, gas trucks sometimes move faster because buyers don’t want the hassle of diesel emissions systems due to the short trips.

As Kelley Blue Book reports, “Diesel pickups generally retain 10 to 15 percent more value after five years compared to gas equivalents.”

At the end of the day, contractors choose trucks based on the kind of work they do.

A residential remodeling contractor who mostly hauls tools and light trailers might find a gas truck perfectly adequate, saving money up front and on maintenance.

A heavy construction contractor pulling skid steers, backhoes, or dump trailers daily will almost always justify the diesel.

“It’s about using the right tool for the job,” Hanson said. “If all you need is a hammer, don’t buy a jackhammer.”

Contractor experiences often speak louder than spec sheets.

Case One: The Excavator Hauler

Jason, who runs a small excavation business in Colorado, swears by diesel. “I pull a 14,000-pound trailer almost every day. My Duramax doesn’t break a sweat. I tried a gas truck once, and I felt like I was killing it on every hill.”

Case Two: The Remodeler

Sara, a general contractor focused on kitchens and additions, runs a gas F-250. “I don’t tow much, just a small enclosed trailer with tools. The gas truck was ten grand cheaper, and I don’t have to mess with DEF. For me, it’s perfect.”

Case Three: The Fleet Manager

A roofing company in Texas runs twenty pickups, half gas, half diesel. Their manager explained, “For crews pulling dump trailers, diesel is worth it. For guys just hauling shingles and ladders, gas saves us thousands.”

No discussion of gas vs. diesel is complete without mentioning the new challenger: electric trucks. The Ford F-150 Lightning, Chevy Silverado EV, and Tesla Cybertruck (lol) are showing up on the streets and at jobsites. While still limited by range and charging, they promise torque like a diesel with the maintenance simplicity of gas.

Contractors are watching closely, but for now, the gas vs. diesel debate remains front and center.

So, gas or diesel - which truck pays off in the long run for contractors? The answer is frustrating but honest: it depends.

If your work demands heavy towing, long highway miles, and you keep trucks until they hit the 300,000-mile mark, diesel is likely the better investment despite higher upfront and maintenance costs.

If your work is lighter duty, mostly local, and you trade trucks every few years, a gas pickup may save you thousands without compromising capability.

There’s no one-size-fits-all. The right choice is the one that makes you money, not costs you money.

In the end, contractors should run the numbers, factor in their specific workload, and remember that the best truck is the one that keeps the business moving forward - whether it sips gas or gulps diesel.

Balancing Payload and Comfort: Choosing the Right Pickup Trim for Work and Family

Off-Road Basics: What Outdoorsmen Should Know Before Leaving the Pavement