Mini MOLLE Bottle Opener - Stainless Steel

888104

Description

Like many great products, the Mini MOLLE Bottle Opener was born from our 2022 April Fools joke product/video, seen below. Each bottle opener is laser cut from stainless steel and tumbled to a uniform industrial-looking finish. LIMITED QUANTITIES.

Engineering

These Mini MOLLE Bottle Openers are much, much more than a place to hang a pouch or a strap. Manufactured from 16 gauge steel using our signature 'block and slot' pattern, they offer the strength and rigidity required to mount heavier gear and equipment.

We used detailed 3D scans of OEM and aftermarket wheels to ensure that your WOLLE panel fits safely and securely with only moderate risk of injury or damage to yourself, other pedestrians and other vehicles.

Features

- Laser cut and CNC punched/formed for perfect fit

- Extremely durable 16ga stainless steel construction

- MOLLE/PALS compatible mounting features

Kit Includes:

- 1x Mini MOLLE Bottle Opener

- Nothing else

Fitment:

- All standard bottle caps

Install

Installation is very straight forward. Follow this guide to see what's involved.

Engineering

Installation

Fitment

Pairs well with

Made in USA

Lifetime Warranty

Lifetime Customer Support

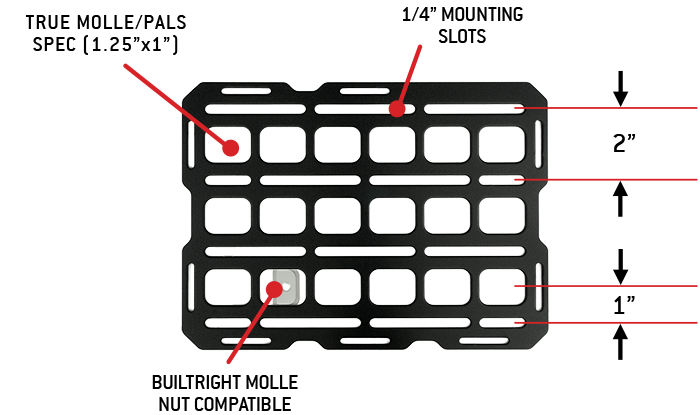

'Block & Slot' Pattern

The term MOLLE has become a bit of a buzzword in recent years and many imitation products have latched onto it, simply cutting square or rectangles into their products. The BuiltRight 'Block and Slot' pattern offers slotted features, designed for use with common 1/4" mounting hardware in addition to correct MIL-SPEC MOLLE/PALS features. Finally, the BuiltRight MOLLE Nuts (sold separately) offer an additional mounting location with a 1/4-20 threaded hole for easy installation.

The Design Process

BuiltRight is an engineering company before all else and we're obsessed with great mechanical design. Each product has a story of ideas, innovation and iteration until it's just right.

Your Bedside Rack System started as a 3D scan of multiple truck beds, in order to understand the manufacturing tolerances that Ford, GM, etc hold themselves to. We then use that data along with CAD files provided by our OEM partners to design parts that will fit your truck perfectly.

Finally, we test those parts using finite element analysis on the computer before sending them out to our network of product testers around the world. Real-world testing happens in Baja, on ranches and job sites across the country and on the icy, salty roads from the Midwest to the Northeast.