MOLLE Nuts | Threaded MOLLE/PALS Fastener

201023

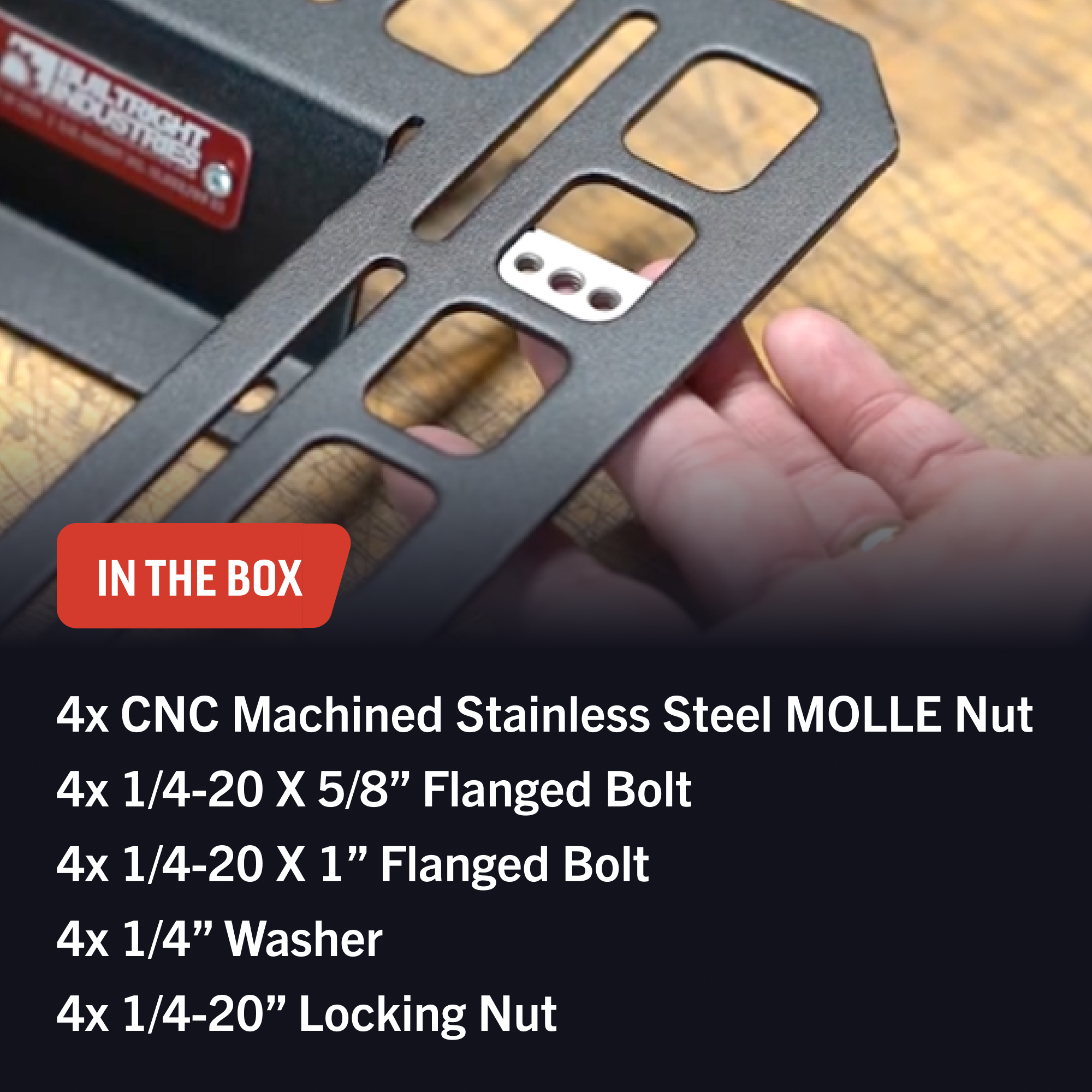

Description

BuiltRight MOLLE Nuts are the ultimate 'nice to have'. For years, we've had customers reaching behind panels with a wrench and/or using large washers to mount things in the larger MOLLE openings in each panel. Save time, save your knuckles and unlock even greater adjustability when using your BuiltRight MOLLE panels. Please note! We've designed these to fit into proper MOLLE sized openings, which are 1" tall. Many of the manufacturers imitating our panels are not adhering to that dimension. On those panels, these will not work.

Details

Installation

Pairs well with

MOLLE Nuts | Threaded MOLLE/PALS Fastener

Made in USA

Lifetime Warranty

Lifetime Customer Support

The Design Process

BuiltRight is, above all, an engineering company, obsessed with exceptional mechanical design. Each product has a story of ideas, innovation, and iteration until it's just right. Whether the design starts with 3D scanning, cardboard templates, or a napkin sketch, our process always ends with thorough testing by our network of desert racers, sportsmen, and regular guys like us.